Furukawa Electric Group defines environmentally friendly products as products or services that contribute to reducing environmental impact or have positive effect on the environment assessing the entire lifecycle of our products.

For the products compatible with environmentally friendly products, the environmental mark “e-Friendly” is displayed on the exterior and the catalogues to encourage their adoption.

The Group's environmentally friendly products belong to one of four categories described below. These links are only available in Japanese.

| Category | Contents |

|---|---|

| Prevention of global warming | Products with functions that contribute to the reduction or absorption/fixation of the greenhouse gas (GHG) emissions through the entire life cycles, or products that have reduced the greenhouse gas in their manufacturing processes. |

| Zero emission | Products made from recycled materials, products designed with easy to-recycle components, products made from materials or with design facilitating volume reduction for lowering waste volume, products designed to share common components with other products or products designed as common components. |

| Elimination of materials that have an impact on the environment | The products that meet all of the followings.

|

| Resource savings | Products that result in overall energy savings by such means as reducing the use of raw materials and components as well as scarce resources, featuring enhanced longevity, allowing easier product and component maintenance, and reducing the use for resources in packaging. |

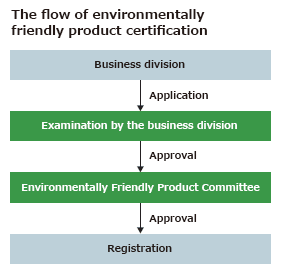

To register products as environmentally friendly, products must go through an application and screening process in their business division and then be examined by the Environmentally Friendly Products Committee, a cross-departmental committee of the Group.

The criteria that products have to meet to be registered as an environmentally friendly product are an overall improvement of environmental performance when compared with existing products based on established evaluation criteria at each stage of the product’s lifecycle: the purchase of raw materials and parts, production, use, distribution and disposal.

In order to increase the ratio of the environmentally friendly products in all the products of the Group , we set targets based on percentage of sales, and confirm our progress and success on this basis.

TOPICS:"Copper alloy products/superconducting products manufactured with renewable energy"

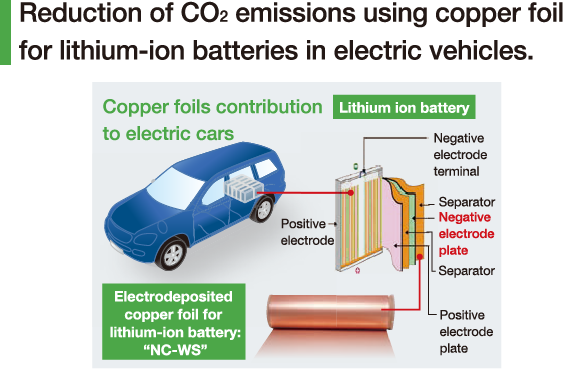

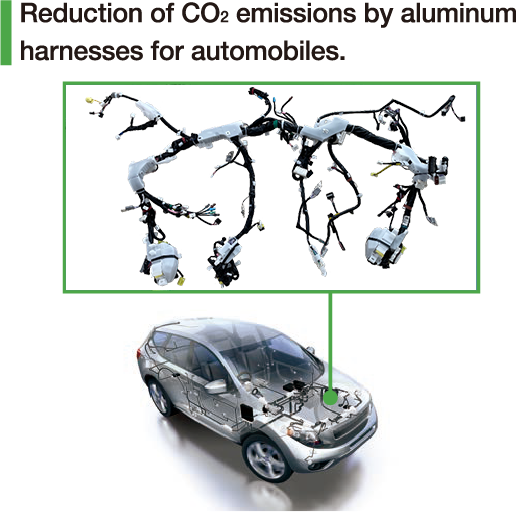

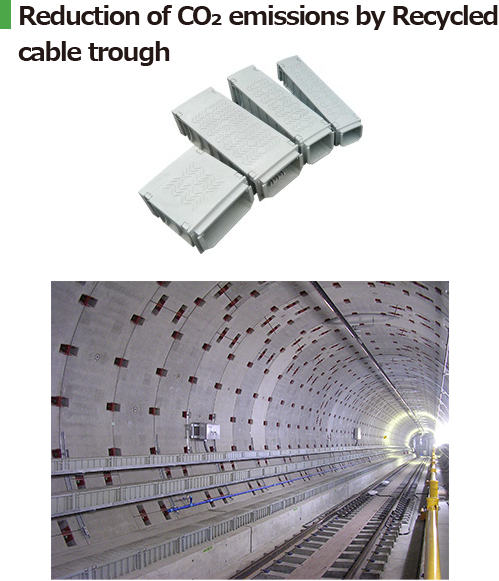

For more than 10 years, our group has been calculating and utilizing Life Cycle Assessment (LCA) for our major products. In FY2022, we established an LCA subcommittee under the Environmental Committee to accelerate these efforts. In addition to visualization through LCA and CFP calculations and efforts to reduce CO₂ emissions, we are working to visualize the avoided CO₂ emissions generated during the use phase of our customers' products, in which our Group’s products are used. Avoided emissions are estimated for “micro ITLA” in the optical communication field, “copper foil for lithium-ion batteries” and “aluminum wire harnesses” in the automotive field, and “GREEN TROUGH” adopted in the field of railways, roads, and renewable energy.

In FY2023, we reviewed scenarios and increased the number of target products. We have estimated the avoided emissions for the offshore wind power generation project installed at Ishikari Bay New Port. We will also calculate the avoided emissions for offshore wind submarine cables, which is expected to expand in the future.

We will continue to expand our efforts to address global environmental issues through our products by increasing the number of environmentally-contributing products and making their performance more visible.

* The scenario was reviewed in FY2023.