Furukawa Electric Group not only adheres to fundamental “legal compliance” but also prioritizes “Safety Conscious Person” and ”Fundamental Safety,” while incorporating “Safety Management” as the three core pillars of our safety activities, aiming to achieve zero accidents and zero occupational illnesses as our basic approach.

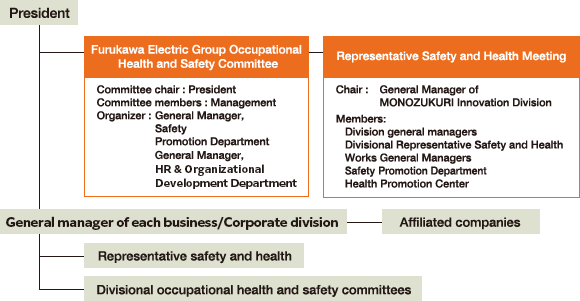

The Group has established the Furukawa Electric Group Occupational Health & Safety Committee, chaired by the president, as the highest body for promoting occupational health and safety at a group level. The committee membership is composed of executives, and carries out deliberation, decision-making, and follow-up activities on policies and initiatives in health and safety for the entire Group.

At our domestic sites with manufacturing departments, we are advancing the development of occupational health and safety management systems. Each site conducts risk assessments and implements measures related to safety and health, promoting occupational health and safety activities.

As of FY2024, the adoption rate of ISO 45001 and OSHMS among domestic sites with manufacturing departments (Furukawa Electric) is 80%.

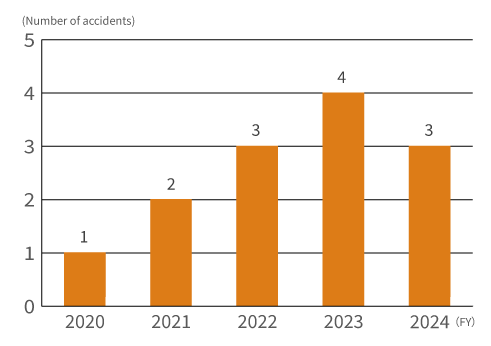

The Company aims to achieve zero lost-time accidents (Furukawa Electric) and is working toward this goal through occupational health and safety activities.

See the ESG Data Collection for details.

In FY2024, the number of lost-time accidents (resulting in 4 or more days of absence) was 3 (Furukawa Electric). The frequency rate of lost-time accidents was 0.26% (Furukawa Electric and domestic group companies). No fatal accidents occurred at Furukawa Electric sites.

In response to occupational accidents, the safety manager at the site where the accident occurs promptly reports to the Safety Promotion Dept., which then escalates the matter to top management. The site conducts a thorough investigation into the root causes and implements fundamental countermeasures, sharing information to prevent recurrence.

*1 Lost-time accidents refer to incidents requiring 4 or more days of absence.

*2 Frequency rate = (Number of casualties / Total actual work hours) x 1,000,000

*3 Data for all industries and the manufacturing sector are sourced from surveys by the Ministry of Health, Labour and Welfare.

We provide education on basic safety knowledge, safety rules and procedures to prevent workplace accidents, and emergency response methods.

At Safety Dojo sessions held at each site and department, we conduct hands-on training using simulators and VR to simulate hazards such as entanglement or forklift blind spots. These activities aim to enhance hazard awareness, deepen learning from past accident cases, and foster safety consciousness and practical skills among employees.

These workshops, incorporating classroom learning and practical training, emphasize strict legal compliance, enhance drivers’ safety awareness, provide the latest knowledge and skills, and focus on preventing occupational accidents. These efforts contribute to improved operational efficiency and motivation.

In addition, we conduct first-aid training and traffic safety seminars.

Furukawa Electric Group has established “Safety and Health Committees” at each department, encouraging employees to actively engage in safety and health activities. Additionally, we hold annual Safety and Health Activities Presentation Meetings to showcase the Group’s safety and health initiatives, recognizing outstanding efforts. In FY2024, 11 teams (including 4 from group companies) selected from various business divisions presented and received presidential commendations.

Furukawa Electric’s safety officers make site inspections at Furukawa Electric Co., Ltd. and group companies whenever an accident occurs depending on the safety performance in the previous fiscal year. They confirm how appropriate the safety measures are and what extent the measures have become established. In addition, they exchange opinions on how to promote fundamental safety in order to prevent any recurrences. In FY2024, inspections were conducted at 4 Furukawa Electric sites, 4 domestic group companies, and 8 overseas group companies, with discussions held.

Furukawa Electric Group promotes Health and Productivity Management in which we strategically address our employees’ health management/promotion from a managerial viewpoint.

Health and Productivity Management

ESG Data (Occupational Health and Safety/Health)