Furukawa Electric is certified ISO 9001 on a business unit basis. By implementing ISO 9001 systems to standardize operations and continuously striving for quality improvement, we aim to contribute to society by providing high-quality products and services from the customer’s perspective.

Additionally, under the Quality Management Policy, the Group promotes improvement activities to achieve “the quality expected by customers.” We strengthen quality compliance as a fundamental prerequisite while advancing initiatives such as the “Quality Enhancement Project” to improve manufacturing quality and the “Risk Free Design (RFD) Project” to enhance design quality in the design and change processes. Through these two projects, we aim to enhance organizational problem-solving capabilities and improve “manufacturing capabilities” to create new value alongside our customers.

At every stage of our operations, from research and development to manufacturing, sales, customer service and management, in all sections and all hierarchies, we always strive to adhere to a PDCA management cycle based on actual facts, maintain and improve our products, customer services and the quality of our operations and put our management policies into practice.

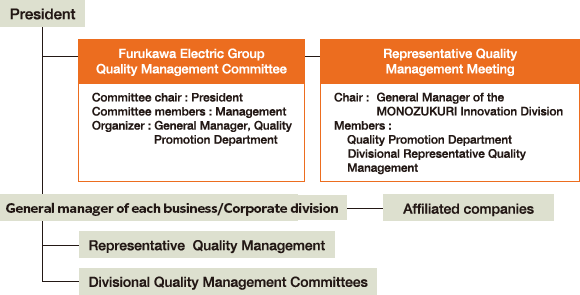

The Group has established Furukawa Electric Group Quality Management Committee, which is chaired by the president, as the topmost body for promoting quality management. Directed by this committee, Divisional Quality Management Committees led by general manager of each business/corporate division promote ongoing efforts to maintain or improve the quality of our products, customer services, and operations.

Thorough quality compliance is a fundamental prerequisite for our business activities. To eliminate quality frauds, strong leadership from top management, robust systems and their execution, and effective monitoring functions are essential. Furukawa Electric Group reinforces compliance awareness through top management guidance, establishes systems to meet customer requirements and expected quality, and strengthens regular inspections for compliance with laws, regulations, and customer requirements. By continuously implementing these measures, we ensure that all business divisions and group companies conduct activities in alignment with these standards.

With the objectives of “enhancing manufacturing capabilities,” “gaining technically valuable insights,” and “reducing failure costs,” all business divisions select critical manufacturing issues and work to resolve them. This initiative also aims to develop personnel with strong problem-solving skills.

In FY2024, we held the Furukawa Electric Group Quality Enhancement Activities Presentation Meeting. Representatives from all business divisions shared their activity reports, fostering mutual learning and improvement. Based on a standardized problem-solving approach, participants offered suggestions to enhance technical challenges in other divisions, gaining new insights and opportunities for improvement.

In order to achieve the quality expected by customers, it is important to identify problems at the design and development stage and to take appropriate measures before starting the production. In this project, we are working to improve problem identification and solution in the design development and change process, and to improve the mechanisms for effective implementation of these processes.

We conduct ongoing training to foster the adoption of fundamental concepts and enhance leadership skills. By implementing and practicing preventive mechanisms, we have promoted the internalization of these concepts. Additionally, we conduct self-check activities to ensure issues are resolved in the design, development, and change processes, continuously advancing efforts to improve problem identification and resolution capabilities. Furthermore, we ensure that the concepts and systems developed through this project are steadily adopted across all business divisions through ongoing efforts.

This system is shown in the "Guidelines" regarding the design and development that the Group has independently established. By the guidelines, each business division is promoting the standardization that is appropriate for each business and continuously implements improvements to address problems that emerge while operating the system.